How Desiccants Protect Against Moisture During Transportation

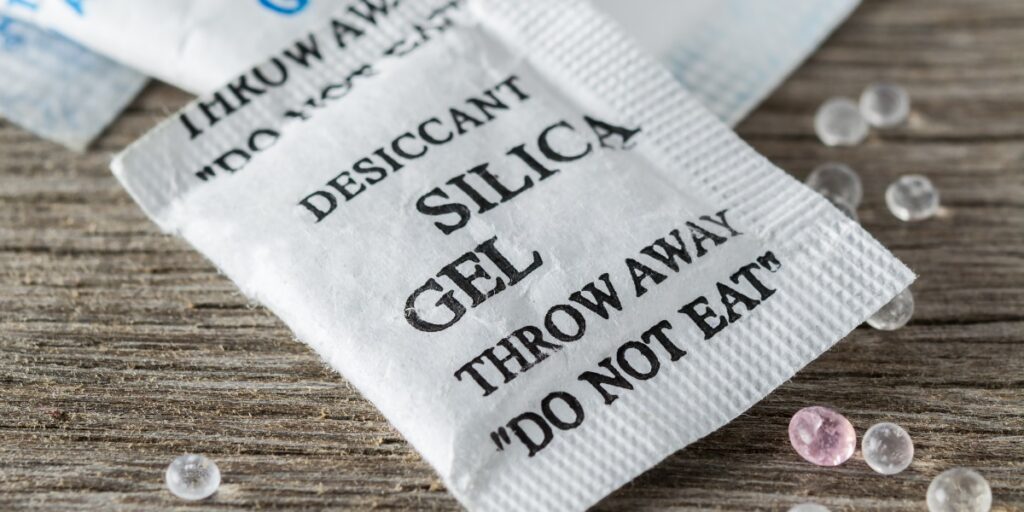

Desiccants play a crucial role in protecting goods from moisture damage during transportation, ensuring that products arrive at their destination in optimal condition. These moisture-absorbing materials are especially important in industries where humidity control is critical, such as pharmaceuticals, electronics, and food. Understanding how desiccants work and their benefits can shed light on their importance in the shipping process. Desiccants are materials that absorb moisture from their surroundings, thereby controlling the humidity level in an enclosed environment. They are typically made from substances like silica gel, activated alumina, clay, or molecular sieves, each offering different moisture-absorbing properties. Desiccants are commonly used in packaging to protect products from the damaging effects of moisture. Desiccants work through adsorption, a process where water molecules adhere to the surface of the desiccant material. In contrast to absorption, which involves the material absorbing water into its structure, adsorption involves water molecules sticking to the surface of the desiccant. This process reduces the amount of free moisture in the air within a sealed container, preventing condensation and maintaining a controlled humidity level.

Benefits of Using Desiccants

Prevention of Mold and Mildew – Excess moisture can lead to the growth of mold and mildew, which can damage products and compromise their quality. Desiccants help prevent this by keeping the humidity level within the container low.

Protection of Sensitive Products – Products such as electronics and pharmaceuticals are particularly sensitive to moisture. For example, electronic components can short-circuit or corrode when exposed to moisture, and pharmaceuticals can lose their efficacy. Desiccants ensure these products remain dry and functional.

Reduction of Shipping Damage – Moisture-related damage, such as rust, corrosion, or deterioration, can occur during shipping. Desiccants help minimize these risks by maintaining a dry environment, thus reducing the likelihood of damage and ensuring that products arrive in good condition and what is a desiccant.

Extended Shelf Life – By controlling moisture levels, desiccants help extend the shelf life of products. This is especially important for food items, which can spoil quickly if exposed to high humidity.

Types of Desiccants

Silica Gel – Silica gel is one of the most common desiccants. It is highly effective at adsorbing moisture and is often used in small packets placed inside packaging. It can absorb up to 40% of its weight in moisture.

Activated Alumina – This desiccant is known for its high adsorption capacity and is often used in situations where high moisture removal is needed. It is effective in a wide range of temperatures and humidity levels.

Clay Desiccants – Clay-based desiccants are less expensive and have a lower adsorption capacity compared to silica gel. They are often used in bulk packaging and for less sensitive products.

Molecular Sieves – These are highly specialized desiccants with the ability to remove specific molecules from the air. They are used in situations requiring precise moisture control.

Jalon desiccants are an essential component of moisture control in transportation. By absorbing excess moisture, they prevent condensation, protect sensitive products, reduce shipping damage, and extend shelf life. Whether using silica gel, activated alumina, clay, or molecular sieves, selecting the right desiccant for the specific needs of the cargo can make a significant difference in maintaining product quality and integrity during transit.